Manual centrifuge for two machines

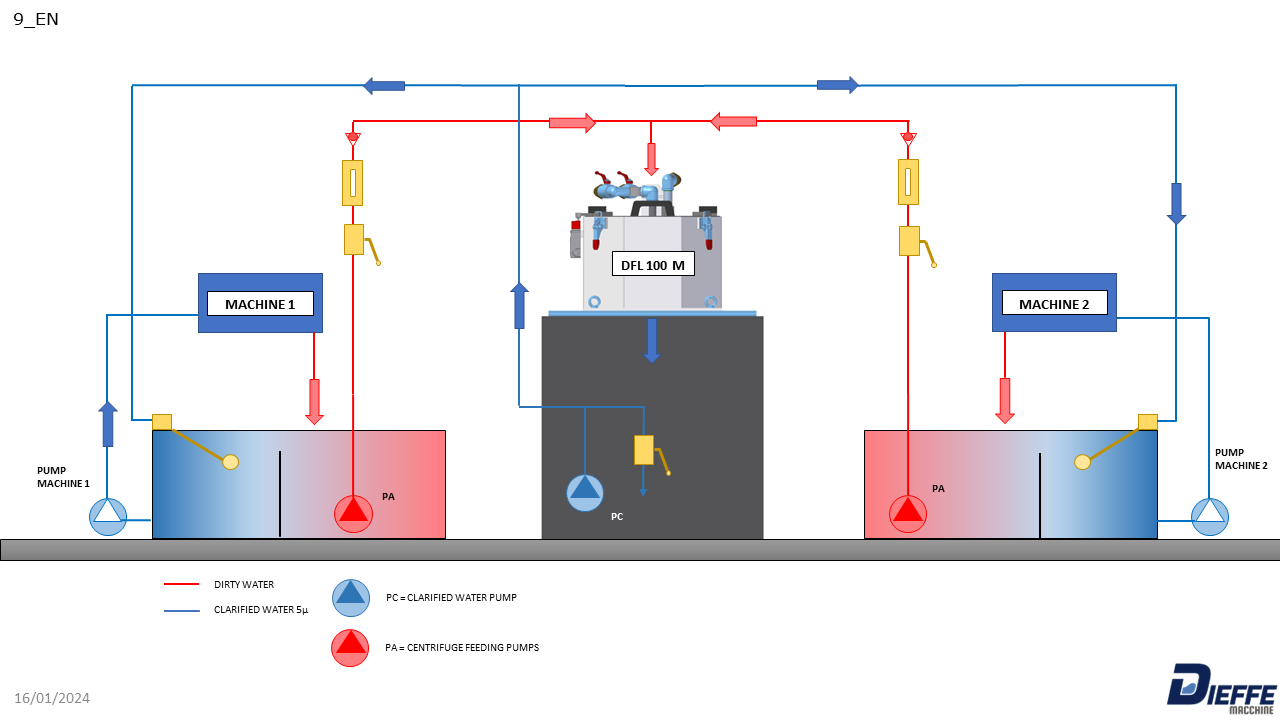

The purification process by centrifugation with manual discharge takes place in the following way: the production waste, consisting of water and silica sand removed by grinding from the glass, converge in the special tanks of the machines. From these tanks by means of submersible pumps and special pipes, the liquid is pumped into the centrifuge, Duplex version, capable of controlling two machines.

Before entering the centrifuge, the dirty water is passed through flowmeters, fixed on the centrifuge tank, to view the flow and the flow rate of each user will be regulated by means of ball valves.

At this point the centrifugal force will thicken the mud and impurities contained in the dirty water on the walls of a thermoforming basket with acrylic material for sludge recovery.

A pipe located inside the centrifuge will have the task of recovering the clarified water which will then be collected in the appropriate tank below. From here a submerged pump will relaunch the purified water to the machines of use.

The sludge produced by the centrifugation process will be removed manually, removing the basket, and disposed of in the appropriate bags. The sludge recovery basket in acrylic material is equipped with a residual water discharge system to prevent the operator from differentiating the discharge between water and mud and also facilitating the discharge by decreasing the weight of the same.