Centrifuge with fully automatic solid discharge

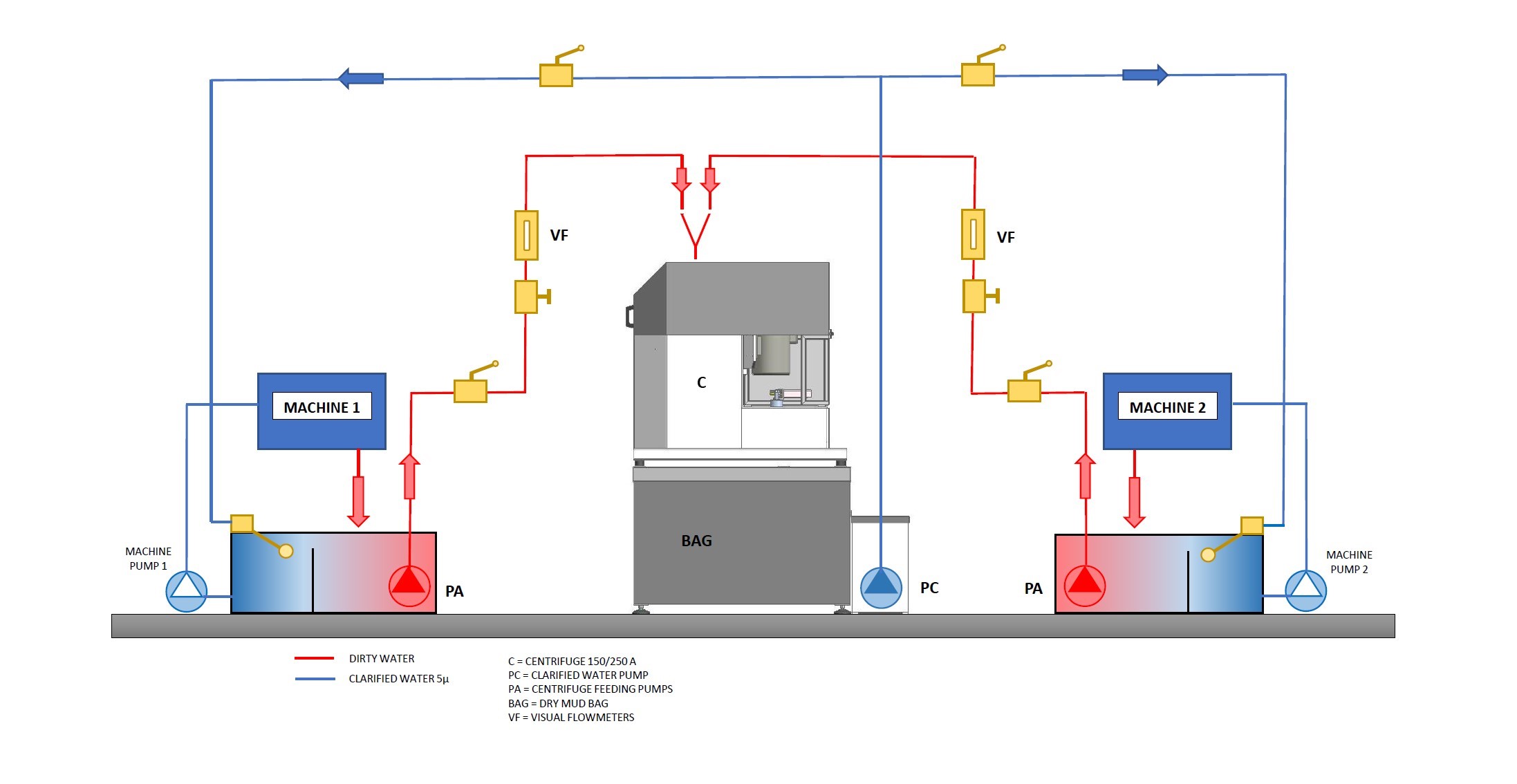

The system consists of an automatic centrifuge working feeded simultaneously by two submersible pumps placed respectively in the tank of the machines. The clarified water produced by the centrifuge is sent to the tank of the machines by means of float ball valves to keep the levels checked. In this way the tanks will remain as clean as possible.

This mechanical centrifugal treatment system is used to remove solids from water used in glass, stone and ceramic materials. The solids which are suspended in the water are separated by a centrifugal action, producing clear water suitable for being recycled and reused by the same process.

The clarification is done by pumping the waste water into the centrifugal drum at a controlled flow, directing it appropriately into the specially shaped and designed rotating drum. The unique designing of the basket produces two actions: the solids are forced on the outside due to their weight compared to the water (force g) and the clarified water is conveyed upwards at the outlet to be recycled.

The water is clarified to 5 μ m (5 microns). This means that solids with a specific gravity greater than one and greater than 5 μm are separated. The clarified water is returned for re-use.

The elimination of sludge produced by the centrifuge is done automatically. At pro-grammed times by keypad on the PLC, the centrifuge will stop to evacuate the accumu-lated sludge. At the end of the operation the centrifuge will restart a new work cycle. The centrifuge can be equipped with a remote start and stop function.